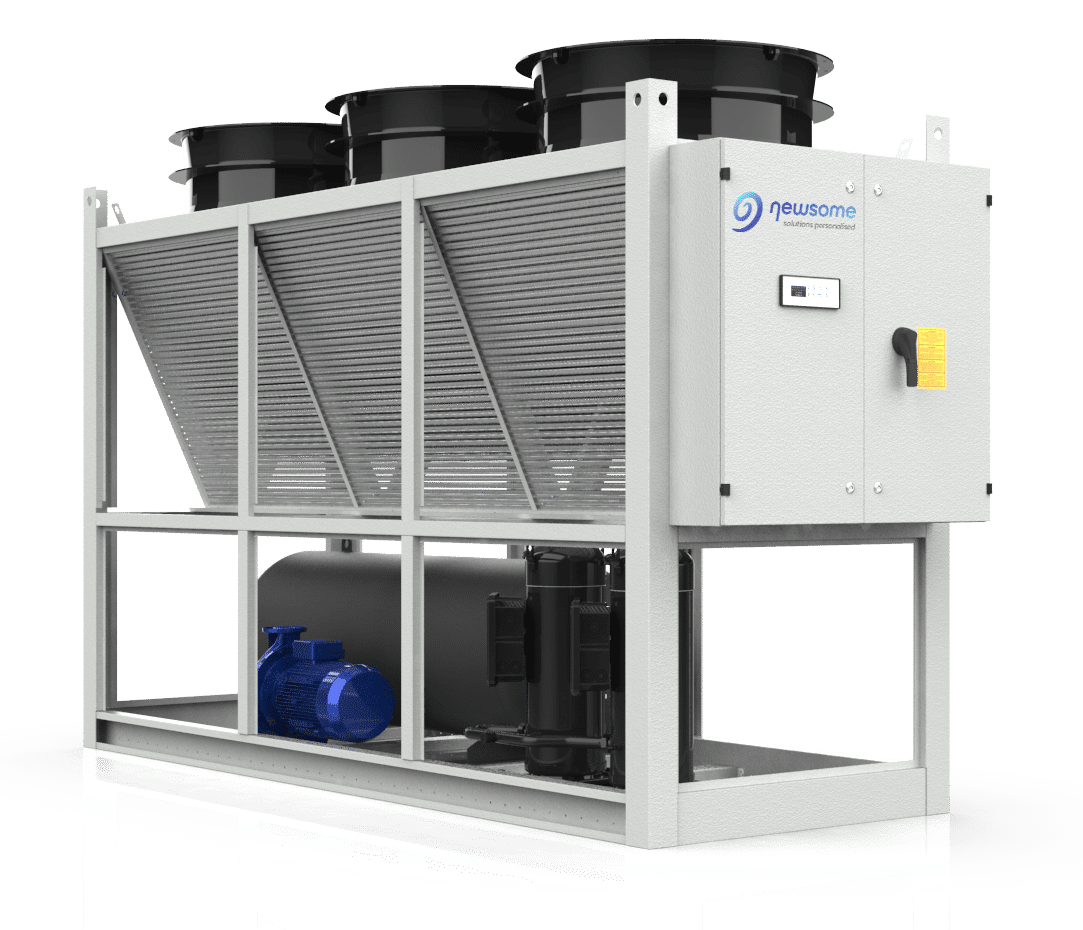

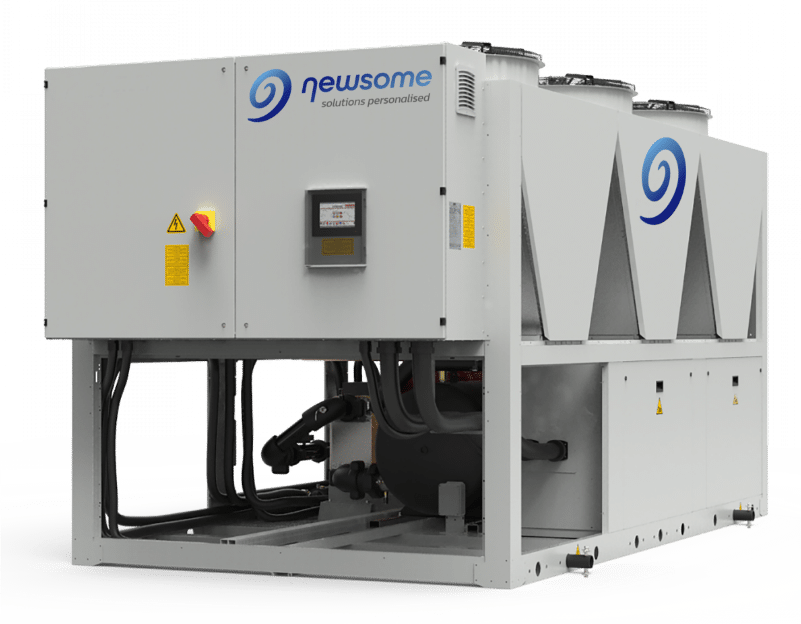

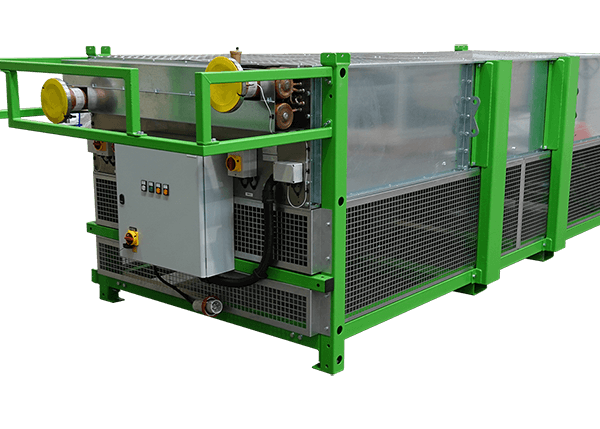

Dry Air Coolers

A Dry Air Cooler (DAC) can supply temperatures between 3*C – 5*C higher than the ambient air temperature in which they sit, whilst Adiabatic Coolers can provide supply fluid temperatures around 3*C below ambient.

Ambient coolers if applied correctly can provide a very cost effective & energy efficient temperature control solution.

Newsome’s dry air coolers are built bespoke to customers needs, although the range covers between 42kW – 3mW

Contact us to find out more about our range of industrial dry air coolers.